|

|||||||||||||||

|

|||||||||||||||

|

Follow the progress of IF32 - data logger and control equipment for rough environment conditions and long term use.

- Built in "Smartphone" interface and free application for control and configuration.

- built on powerful 32-bit u-controller STM32F207

- fully suited for mobile environment

- extremely compact design

- built in easy to use interface

- 8 analogue inputs (4-20mA and/or 0-3.3V)

- RTC (real time clock)

- non volatile memory for parameters and data. Built in easily exchangeable mass storage devices (uSD-card)

- remote upgradable firmware

- built in diagnostics

- reliable and easy cabling communication interface and multi drop protocol

- remote configuration and download of data through built in modem

- several applications ready

- 2D Real time rainflow

- Multi dimensional TAL (Time at level)

- TBM (Time based measurement)

- Crane control system

- LMI (Load moment indicator)

- and more.

- All applications based on a solid RTOS environment.

The above description is an example of our latest powerful platform for measurement and control of mobile hydraulics. Besides being robust and compact, it's flexible and adoptable to almost any need - most likely yours. Our programmers are specialized in implementing our and your"know how" into the software that really becomes the value of your product. Our hardware and operating system is only the platform for your ideas to show - and most important - become profitable.

Follow the link below and send an e-mail describing you and your ideas, and we'll come back with an offer or more detailed descriptions.

Peter Astrom, CEO.

Get more details from Infield instrument

Follow the progress, and some backlash...

This short story below is about our "latest" child - the SC3. If you have the slightest interest in mobile electronics, or just curious of what it's like to be involved in the "birth" of a new product in a small company, I'd suggest that you continue to read this site. Not only for the moment, but continuously. I will try to update this blog like part of our site at least twice a month.

Of course the benefit for us is that we get some publicity, and evan though the chances that you need our product isn't that big, hopefully you can tip of somebody else. Anyhow I'm sure you can learn from both our progress and mistakes.. though we won't hide anything in our story - not evan when the "spirit" leaves... I'll explain that saying later.

Peter.

New Infield designer takes on IF32 challenge.

Hi.

I'm Richard Kihlmark and I've just recently started here on Infield. I

have 15 years of experience from electronic design and embedded programming.

Besides overall design I've worked a lot with MMI:s and the implementation

of LCD:s in rough environment. I'm really looking forward to get a good

"bite" of the many challenges here at Infield.

My former employer before my latest here at Infield, was Nonin Medical AB. Evan though the surroundings were much more pleasant for those products, I learned a lot of the importance of a powerful, yet easy to use, man-machine interface.

In my spare time I'm always developing something useful - for the moment a home heating solution I'm all on fire over...

Looking forward to hear about your needs too.

Best regards, Richard.

April - 2013

The switch from Atmel AT91SAM7A3 to the ST-processor STM32F207 looks as a good thing so far. The ST-processor is extremely well documented compared to the Atmel processor. Although we got every built in peripheral unit we needed running in the SAM7A3 it was really hard. The F207 is a lot more predictable.

We have begun testing circuit solutions on the 3:rd generation prototype cards with SAM7A3 running with intended inputs and loads. The testing is advancing but we still learn a lot the "hard way" about some of the peripherals on the card.

The chosen H-bridge - TLE5205-2G or 06 - show sensitivity to almost anything beyond the narrow area of use. Negative peaks from power supply affects it immediately and not only the H-bridge itself but also the processor. Perfect protection against negative peaks on power supply and protection on control lines seems necessary.

//Peter

August - 2013

The first prototype PCB:s for the platform with the new 32bit ST-processor was ordered during our holidays. Not because of lack of X-rays outdoor, but it was just as fun completing the PCB.

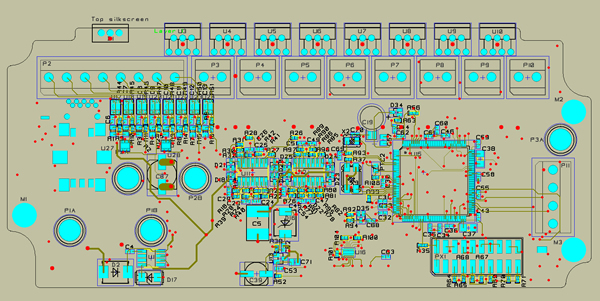

Top view with connectors

The ordering of the components for the first prototypes gave some backlash in shape of problems with two different ESD-filters - 6 and 8-channels - from NXP. We found them at one of our suppliers during design but didn't think they would advertise something they wouldn't sell. No other distributor in Europe or US accepts order below MOQ=4 000 pcs... Ok, we do have great expects for our platform but that was a lot.

I'll get back with more details after building and testing - hopefully including ESD filters.

Best regards, Peter.

November - 2013

Hi.

The testing of the first 32bit ST-platform cards have progressed. Fortunately

the testing results are more promising than our mounting staff's comments

during building... Besides some problems getting the components, and especially

the rare integrated filters, the filters themselves turned out to be really

hard to solder manually. Ok, they are intended for automatic soldering

but it doesn't hurt if it's possible to build prototypes manually.

So far we have our first application running with graphic user interface - that looks really nice - and also packet switched communication with zero packet losses. No tests yet in disturbed environment but "so far so good".

Coming up is porting RTOS to the new processor, although we haven't seen the definite use of it so far but the experience is that a stable OS eases up the work of porting other applications to a new platform - and there are several of them. Time will tell if it was worth the effort.

To avoid too much rest during my Christmas holiday I will start drawing the second prototype PCB. I will of course exclude the dam-ed integrated filters and go for discrete ones. Also step back to 0603 components instead of 0402. Ok, plenty of space is a lack on our cards, but being able to see the component is an advantage, outside the camera and cell phone industry at least. Also the fact that we will split the card in two for better flexibility will give more card space. The main purpose for two cards is different needs of user interface - graphic LCD or plain box with need for external terminal. Also different needs of external communication.

//Peter

New programmer on site

Hi!

My name is Michael Rask. I come from a small village Hassela in the north

of our region, Hälsingland. I've been on Infield since the end of

2013 with focus on software development.

Before Infield I studied to Batch. of sc. in electronic design and programming at the University of Umeå. Much of the time in the dedicated courses was spent on embedded programming and design. My graduation work was wireless control of hydraulic driven forestry machine at a local company.

I spend much of my time off work, rehearsing with my band "Tre ögon i bäcken" where I play the guitar. We celebrate 10 years anniversary this summer.

/Michael

May - 2014

Ok, I may not be the most frequent "blogger", but hopefully an interesting one. Since November I have completed the schematics and also the PCB design of 3:rd generation card. I didn't satisfy with 0603, I went all the way to 0805 size and all filters with discrete components. The production people looked very pleased all the way... The emphasis has not only been easier manual mounting but also fully EMC (electro magnetic compatibility) which also increased the no. of components significantly. Also the fact that some of the unshielded space gets wasted for component placement didn't ease PCB design. Anyhow - almost finished.

We have also had "new recruits" this winter and spring from a local school, helping with and learning the whole chain of our company, including electronic CAD, mechanical CAD, purchase, marketing, etc. We planned and executed the practice in a very structured way, making it as educating as I think it's possible. The practice ended with an exhibition, planned and held by our students, on the same school with many companies from the community participating with their students. We took the chance to launch our new platform for "Timber crane control use".

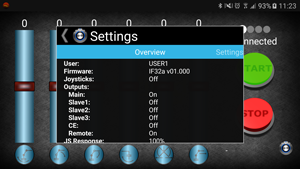

The system we showed was built with 2:nd gen. boxes - main and slave - and also a new Blue tooth modem for smartphone interface. To my knowledge we are absolutely first with up and running control system for cranes with remote control from an ordinary smartphone. For sure we have a wide range of really good pro joysticks for the ordinary use of the crane, but for lowering stabilizers and placing the crane after securing the load - quite nice!

Below you see our new system together with our new programmer in deep thoughts - Michael Rask. Behind on the screen you have a simultaneous copy of the phone when in "linear lever mode", e.g. controlling the crane. To the right is the crane valve with hydraulic power pack simulating the crane. The two different joysticks on the table were "different" on purpose for compare.

The new system launched on a local exhibition draw some real attention from the visitors, even though almost none had any connection to the timber crane business. On the other hand we had celebrate visitor from the local press, and one could think that a brand new electronic product, completely developed in our small village would earn one or two rows in the local paper but no... We'll have a band, and perhaps some dancers, next time. Brand new hi tech products doesn't seem to be enough for journalists.

Much more encouraging were our young assistants, getting ready before opening, and then proudly presenting theirs and our work. Here they are testing the system for the first time. As always on these kind of occasions the paint was still drying...

//Peter

June - 2015

"Long time no..." Sorry to have been neglecting you. On the other hand we've got a lot of new exciting things to launch in the near future. Some of them will be unique solutions for our market. Speaking about market, we've hired a new skilled marketing director - Per-Anders Dahlqvist - who recently left Hiab. He and I will focus on targeting the new platform for:

- control systems and safety systems for timber handling cranes;

- safety systems for general cargo cranes.

This spring we shipped the first safety system based on our new platform to a lorry mounted timber crane. Some old function that are mandatory in the CE standard (EN12999) but several new functions that add value to the driver in his day-to-day work.

The control system is also progressing and the field tests are on. Among others we have designed our own remote control from the start. E.g. you won't find anything like it on the market - yet. Fast switch between 24 hydraulic functions, immediate update of direction and chosen functions, several simple unique solutions - like no changes of battery needed, integrated personal alarm, etc.

I hope to show you more in the near future.

//Peter

August - 2015

Ok, not that long time - I'm improving. Just recently back from the local exhibition "Mittia" in the village of Ljusdal - even more surrounded by forest than we are. The visit payed off in form of some interesting news from our colleagues in the market of control systems. Of coarse there were several crane and other manufacturers who showed lots of interesting news.

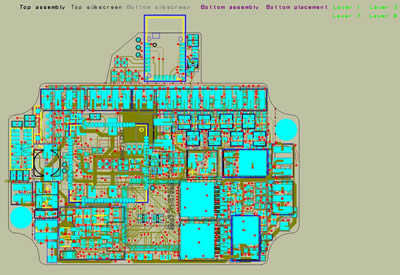

Otherwise our platform is progressing with a new "small box" card ready (previously called modem card) for manufacturing of the PCB. I'm waiting with that to hopefully also have a new version of the main box.The design is merging to both boxes having the same possibility besides the no of power outports which the small box has 4 (2 bidirectional) of and the main box 16 (8 bi dir). The small box, with all that functionality took some heavy effort to design. Below you see a screen dump from the CAD environment. Evan though you see both sides I can guarantee not that much free space here...

Ok, next time I hope to give you the latest news from to ongoing field tests and hopefully some pictures from the second remote control prototype. The base is ready but the phone/modem box holder is still to be drawn.

September - 2015

Big and good news! Since this summer we have more than one on going field test of crane control system based on our new IF32-platform - fully smartphone controlled. Not only can the driver configure the system from his or her phone, but also maneuver permitted functions. In close distance all, but lying on the beach - perhaps only a few selected, like heaters, etc...

Of course we have the usual pro joysticks from Sakae/Caldaro in the crane cabin as the main maneuver place but as we expected the drivers appreciate the possibility with the smartphone to fold the stabilizers and place the crane after tying the load.

We also intend to add our new remote control with the same pro joysticks to the tests in the near future. To make it easier for you to make up your own opinion we will link some videos on youtube here as soon as possible.

August - 2016

Ok, I've really neglected you again. On the other hand we've been more bussy than ever inventing new unique safety functions and speeding up the work for the forest crane user. Probably making our new control system for forestry cranes based on the IF32 platform the safest and fastest the world has seen.

Safe for the user and the surrounding. We've functions like inhibited crane use when support legs are up, inhibited tractor movement when support legs are down or crane unparked, a really user friendly and easily activated personal alarm for the lone user in the woods, and much more.

"Speed" thanks to our cooperation with the world leader in precition hydraulics - Olsbergs hydraulics - and some really nice features from us. We've adopted their smallest block to our electronics and made it an unbeatable team. The crane should feel like a part of the crane driver.

Almost all will be revealed on the Mittia exhibition the 26:th to the 27:th of August. Come and visit us in stand B06 and try controlling a crane with the phone for the first time.

August - 2016, after Mittia exhibition

Puh, the Mittia is finally over. We worked hard and to our joy we had lots of interested visitors both days. The weather was fine the week before the exhibition and on Sunday after, but constantly raining on the first day and more or less storming the second day. The weather could in other words with a bit of luck been better.

Despite the weather we revealed some of our news, like:

- first smartphone controlled crane ever;

- personal alarm for the forest worker;

- safety reminder for not using the stabilizers when operating the crane;

- safety lock for unfolded crane and stabilizers when moving the tractor;

- and more.

Below you see some photos from the exhibition.

Our staff in our stand.

Micke and Stefan - me to the right.

Our vehicle in action. Two of our visitors and one with the remote control to the left.